One of the arguments that I've heard against the "blasting" explanation asks "why would they laboriously drill all those holes and then not blast them?" There are two key assumptions buried in this question that are worth unpacking and discussing.

How Long Does it Take to Drill a Hole in Stone?

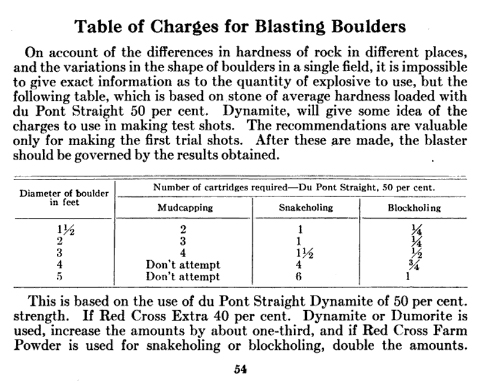

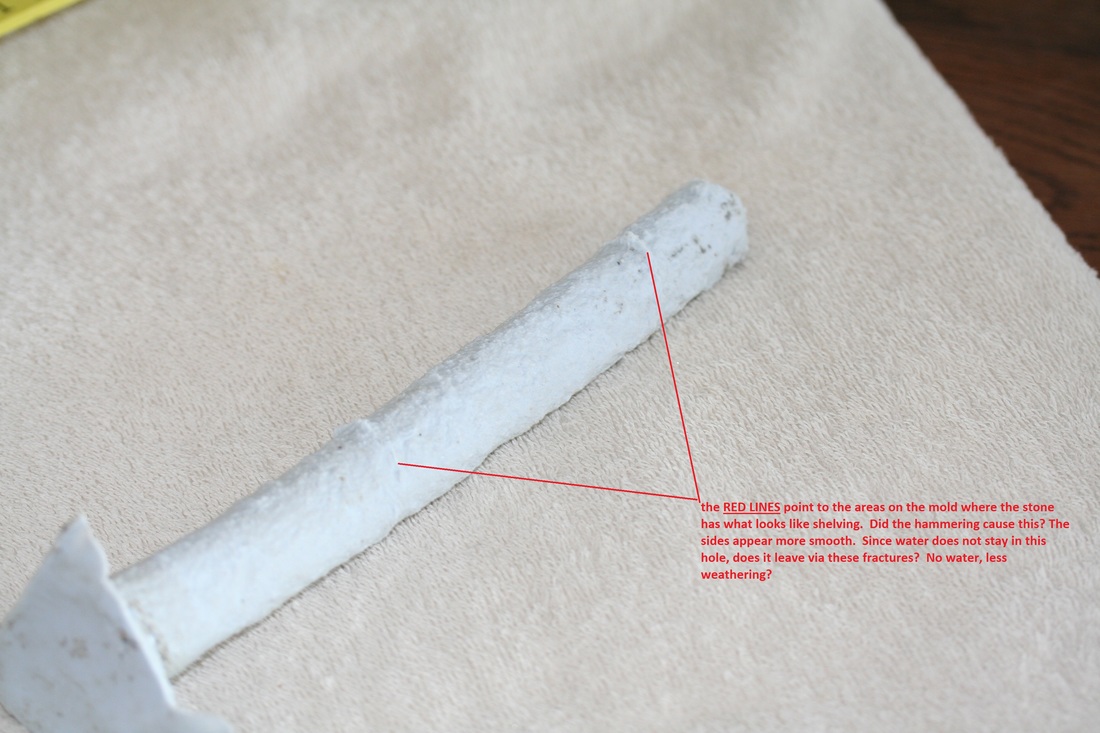

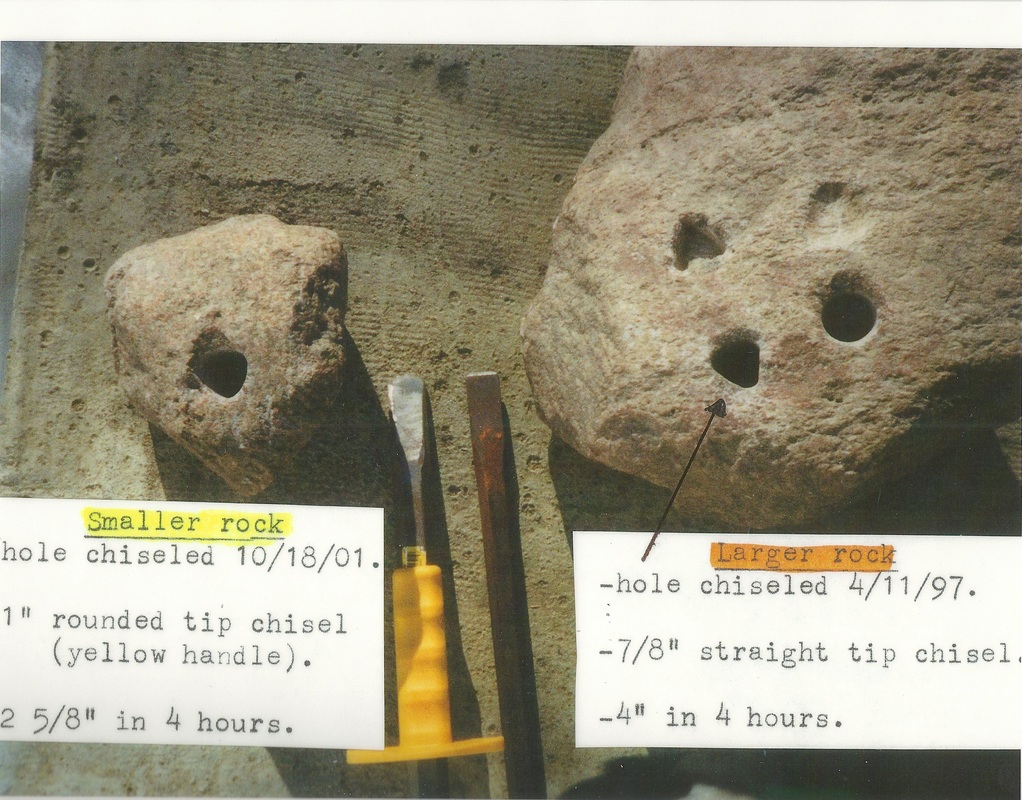

First, the issue of effort: was it really that "laborious" to drill stone holes? It is hard physical labor, for sure, but the data we have suggest that creating a hole in a piece of granite is not an all day endeavor. The experimental results shown in the photograph provided by Judi Rudebusch (here, sixth photo) describe eight hours of labor to create two holes together totaling less than an eight inches deep (i.e., less than one inch per hour of work). That's way out of line with other sources of information.

- The experiment conducted by Frederick Pohl (reported by Mary Gage and James Gage, The Art of Splitting Stone, 2005:48) resulted in a hole 1 1/4" deep in five minutes with one person drilling;

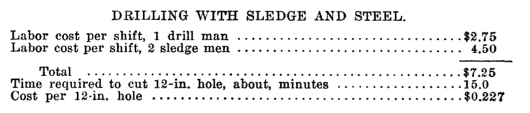

- The Handbook of Rock Excavation (1916:640) reports that a three-man crew can produce a 12" deep hole in 15 minutes;

- The world record for single-person stone drilling in competition (3/4" bit, 4 lb. hammer) is 16.34" in 10 minutes;

"Gee, whiz, I had to crank the grindstone for ’em to sharpen them chisels. You know, you had a chisel this long [showing about a foot and a half]. And then it was about as big as your finger. And then it was sharp, you know, sharpened, and then you took it like this and then you held it on the stone and then you gave it a crack and, you know, they were experts at turning it, see? And then they turn it, and then they gave it another crack, and that’s the way, after a while, the chisel went down in the stone. And then they dug the scrap out and they kept on drilling until it was about this deep [showing about eight inches]. Then they put powder. . . . in there, black powder, and then if it was a big stone you’d have to make another hole over here and another hole over there. And then they set fire to it and blasted it. And it cracks nice."

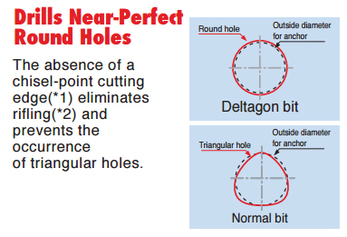

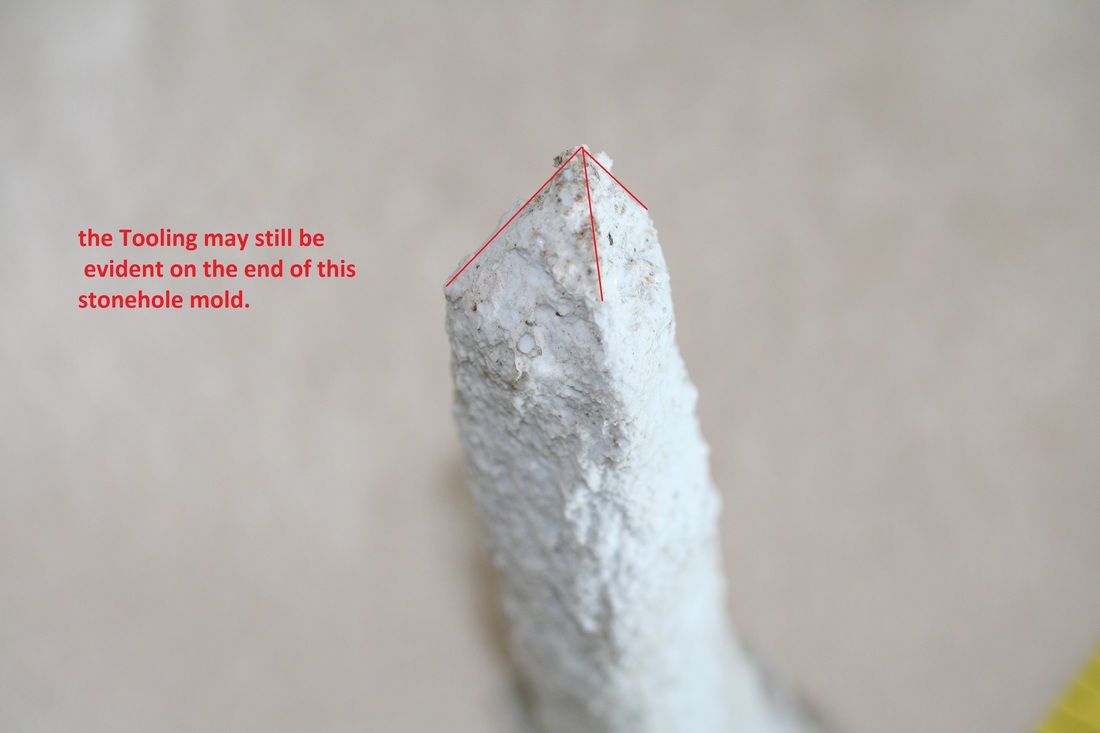

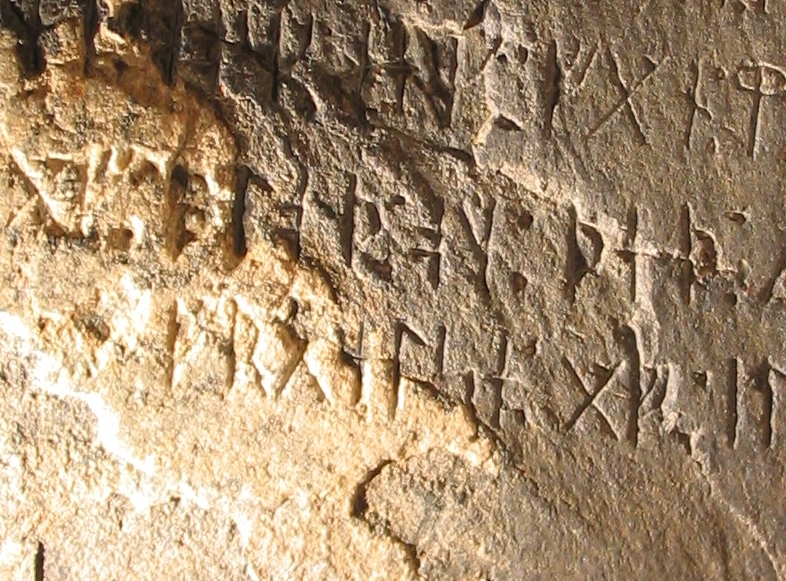

The account doesn't say how long it took to drill each hole, but it does tell us that they were using hand drills (apparently with a straight "chisel" bit edge), to produce holes about eight inches deep to accept a charge of black power (gun powder). Those holes would have been triangular, as the triangular shape is produced naturally by the "wandering" of a straight-edged bit. The informant tells us that the chisel was "about as big as your finger," which suggests to me it was less than 1" wide.

Were the Holes Really Left Unblasted?

The second assumption embedded in the question is that the holes were left unblasted. In some cases, that's almost certainly true. Here is an account from a newspaper story I found posted on the website of the Pelican Rapids (Minnesota) Chamber of Commerce:

"Dr. Paul S. Hanna, an Oxford educated historian and native of Fargo, spent boyhood summers on Pelican Lake. As a child he heard the Viking legends and puzzled over holes he found drilled in rocks along the shore of Cormorant Lake. After World War II, he set out by canoe to explore logical Viking river routes north of Winnipeg. He found no mooring stones, no artifacts. But he did find the most awe–inspiring rapids. After nearly being drowned on several occasions, he became convinced no Vikings sailed upriver from Hudson Bay. "The idea," he says, "that Vikings sailed long ships into Minnesota lakes is utterly preposterous. If Vikings came to Minnesota, they most certainly walked."

If Vikings did not drill those holes, who did? Lillian Kratzke of Pelican Rapids says the Cormorant boulders were drilled by her father, Willie Anderson. During the winter of 1908, Mrs. Kratzke says, her father was looking for building stone. The snow was deep and rocks hard to find—except along the lakeshore where the wind had blown away the snow. Willie struggled through three holes, intending to pack them with explosives. Daylight and determination failed him before too long. By the time he got back to the project, spring had come and he found more convenient rocks."

There's one example of stone holes drilled but never blasted.

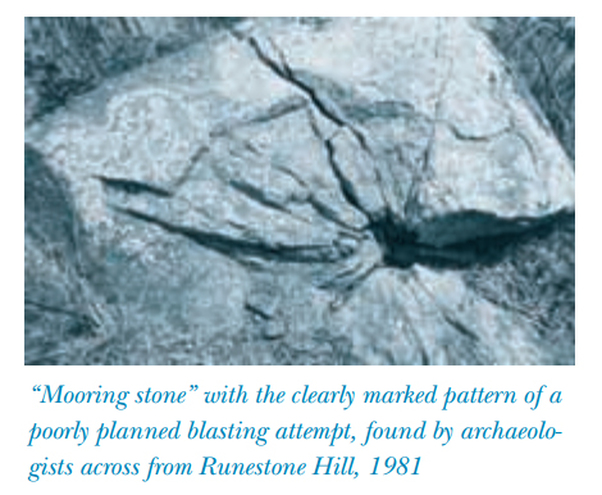

Logically, however, I think that many of the holes in fact were blasted, but unsuccessfully. The literature from the late 19th and early 20th centuries makes it clear that dynamite (invented in 1867) was a far more effective explosive for breaking boulders than gunpowder. Prior to the use of dynamite, it would have been prohibitively difficult/expensive to use "block-holing" methods to break up very large boulders. Boulders that were mostly buried (so-called "hard heads") would have been very tough cases. I think holes drilled in the tops of these stones were attempts to break them so they could be removed. The mass of the stones would have made the use of gunpowder charges ineffective in many cases, leaving unbroken rocks that have been perforated by seemingly "forgotten" stone holes. In some cases, we have examples where such stones appear to be cracked but were never removed.

"Four holes have been drilled into the stone in different directions.... The depth and diameters of these holes are not the same. The two horizontal holes are six and nine inches deep, and their diameter is about one and three-eighths inches. The third hole is sixteen inches deep and one inch in diameter. The fourth hole is five inches deep and also one inch in diameter."

I have a couple of other observations that are relevant to the "stone hole" question. Feel free to comment on these if I'm missing something.

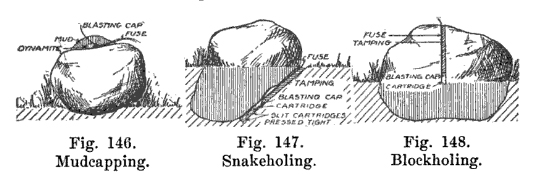

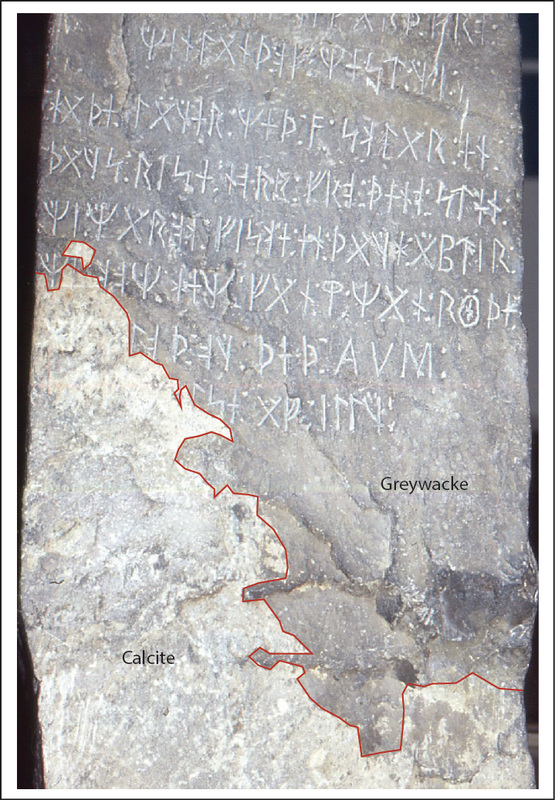

The dimensions of sticks of dynamite are apparently somewhat standardized, with a diameter of about 1.25 inches. The minimum diameter of a stone hole drilled to accept a stick of dynamite, therefore, would have to be 1.25 inches. Round holes of this size can be produced with a "star drill," the bit of which has multiple edges. Star drills produce round holes rather than triangular holes (required to slide the dynamite into the hole), but require more effort than a straight-edged drill to produce the same depth of hole.

In the days before dynamite (i.e., pre-1867), a straight-edged drill would have been preferred because it produces a hole faster. The tendency toward triangular shaped holes would have been inconsequential, as the hole only needed to accept a charge of powder rather than a cylindrical object (a stick of dynamite). The holes could also be smaller than 1.25 inches in diameter.

1. The triangular holes were intended for gunpowder blasting. These holes may pre-date 1867, but they don't have to. As shown in the Trow article, farmers in Minnesota were still using gunpowder to blast rocks well into the late 1800's and probably beyond. The holes were created using a straight-bit chisel. This tool is more efficient for drilling into stone than a star drill. The propensity to produce triangular holes is inconsequential when the material to be inserted is a powder and a not a solid, cylindrical object. Smaller mean size is likely as there is a positive relationship between bit diameter and drilling effort (larger diameters require more effort) and there is no minimum size constraint imposed by the size of the object to be inserted. The mean diameter of triangular holes is therefore likely to be less than 1.25 inches.

2. Round holes and "star" holes were intended for dynamite blasting. These holes post-date 1867. Because the holes were intended to accept sticks of dynamite, they should be larger than 1.25 inches in diameter.

RSS Feed

RSS Feed